1s LiFePO4 BMS for 1 Cells in Series 3.2V BMS

Product Description

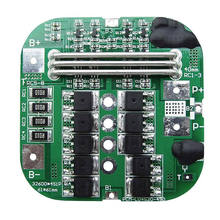

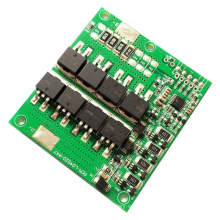

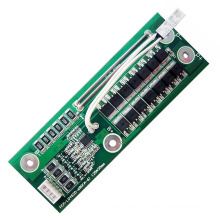

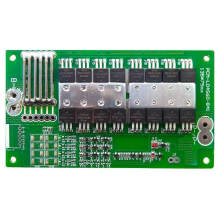

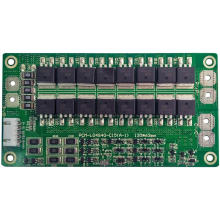

PCM For 1S Li-ion/Li-polymer/LiFePo4 Battery Pack(PCM-L01S03-596)

Quick Detail:

Brand Name:QUAWIN/OEM

Model Number:PCM-L01S03-596

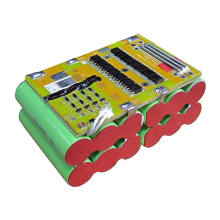

Specified Types: 1S Li-ion/Li-polymer/LiFePO4 Battery Pack

Place of Origin:Guangdong China (Mainland)

Charging Voltage:

Li-ion/Li-polymer:4.20V±0.025V

LiFePO4:3.60V±0.025V

Max. continuous charging current:3A

Colour of PCM:Green

Size:Φ16.5mm

Delivery time:5-7days

Warranty:12 months

Packaging & Delivery:

. Netural labels,Antistatic bag /white box and standard export carton/customized

. Netural packing/Carton box with less than 10KGS

. Delivery Detail:sample within 3 work days,7~15 days for bulk order

Product Advantages:

1). Green product

2). One year warranty

3). Excellent safety performance

4). Short circuit testing passed

5). Overcharge testing passed

6). Over discharge testing passed

7). Original imported material:IC from Japan,MOS from USA,Components from Sumsang.

8). 1.2m drop testing passed

Shipping terms:

1).Samples checking: sending by Express ( DHL/UPS/FEDEX/TNT,by air)

2).Bulk production: sending out by cargo shipping / air freight / Express(DHL/UPS/FedEx/TNT),or we can accept other shipping terms according to your requirements.

3).We are not responsible for any accidents, delays or other issues that are caused by the shipping.

Safety Precaution:

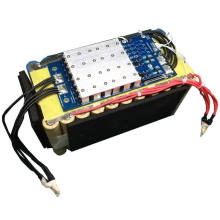

1,Please strictly follow the directions to connect the PCB to the battery. Usually there's voltage in the battery at all time, so operator should connect one single line after other starting from terminal B, following the order from low voltage to high voltage, otherwise it can cause irreparable damage.

2,During the installation, pay attention to small metallic particles that can stick to the protection board.

3,Follow the standard rules when making connections between the protection board and the lithium-ion battery.Operator should not run any wire across the back of the protection board. Keep them along the side of the board instead.

4,When setting up the protection board, be sure to use a hard epoxy board as an interlayer, to prevent short-circuit caused by the components on the back of the protection board.

5,Both resistive load and inductive load can be used to test battery packs that use this PCB, but not electronic load. Testing with an electronic load will lead to the breakdown of the MOS components on the protection board.

6,Select proper wire gauge to prevent temperature increase from high discharge current (when wire gauge is too high) and excessive voltage drop (when wire gauge is too low).

7,When the PCB is to be installed inside the battery's housing, the user must fully take heat/electric insulation and tightness into account to prevent internal short circuit.

8,Keep any fully charged battery away from children.

9,If any abnormality is detected during use, please stop using the product immediately and notify professional technician to conduct inspection and maintenance.

Quick Detail:

Brand Name:QUAWIN/OEM

Model Number:PCM-L01S03-596

Specified Types: 1S Li-ion/Li-polymer/LiFePO4 Battery Pack

Place of Origin:Guangdong China (Mainland)

Charging Voltage:

Li-ion/Li-polymer:4.20V±0.025V

LiFePO4:3.60V±0.025V

Max. continuous charging current:3A

Colour of PCM:Green

Size:Φ16.5mm

Delivery time:5-7days

Warranty:12 months

Packaging & Delivery:

. Netural labels,Antistatic bag /white box and standard export carton/customized

. Netural packing/Carton box with less than 10KGS

. Delivery Detail:sample within 3 work days,7~15 days for bulk order

| Items | Specifications | ||

| Lithium-ion/Lithium Polymer / | LiFePO4 | ||

| Charge | Charging voltage(CC/CV) | CC/CV:4.2V | CC/CV:3.6V |

| Maximal continuous charging current | 3A | ||

| Discharge | Maximal continuous discharging current | 3A | |

| Low current consumption | Current consumption on operation | <10µA | |

| Current consumption at power down | <0.1µA | ||

| Cell-balance | Cell-balance detection voltage | ||

| Cell-balance release voltage | |||

| Cell-balance current | |||

| Over-charge | Overcharge detection voltage | 4.25±0.025V | 3.900 ± 0.025 V |

| Overcharge release voltage | 4.05±0.05V | 3.800 ± 0.050 V | |

| Overcharge delay time | 0.5S-2S | ||

| Over-discharge | Overdischarge detection voltage | 2.50±0.062V | 2.00 ± 0.080 V |

| Overdischarge release voltage | 3.0±0.075V | 2.30 ± 0.100 V | |

| Overdischarge delay time | 50-200mS | ||

| Discharge overcurrent | Discharge overcurrent detection voltage | 0.2V±0.015V | 0.10 ± 0.015 V |

| Discharge overcurrent delay time | 5ms-15ms | ||

| Discharge overcurrent protection | 5.5±1A | 2.5-3.5A | |

| Release condition | Cut-off-load | ||

| Short-circuiting protection | Load short-circuiting detection voltage | ||

| Detection condition | Exterior short circuit | ||

| Load short-circuiting detection delay time | 100 ~ 600µs | ||

| Release condition | Cut-off-load | ||

| Internal resistance | Static Drain-Source On-Resistance | <50m(B- to P-) | |

| Temperature | Wide range of operation temperature | − 40 ~ + 85 °C | |

| Storage Temperature Range | -40~+125ºC | ||

Product Advantages:

1). Green product

2). One year warranty

3). Excellent safety performance

4). Short circuit testing passed

5). Overcharge testing passed

6). Over discharge testing passed

7). Original imported material:IC from Japan,MOS from USA,Components from Sumsang.

8). 1.2m drop testing passed

Shipping terms:

1).Samples checking: sending by Express ( DHL/UPS/FEDEX/TNT,by air)

2).Bulk production: sending out by cargo shipping / air freight / Express(DHL/UPS/FedEx/TNT),or we can accept other shipping terms according to your requirements.

3).We are not responsible for any accidents, delays or other issues that are caused by the shipping.

Safety Precaution:

1,Please strictly follow the directions to connect the PCB to the battery. Usually there's voltage in the battery at all time, so operator should connect one single line after other starting from terminal B, following the order from low voltage to high voltage, otherwise it can cause irreparable damage.

2,During the installation, pay attention to small metallic particles that can stick to the protection board.

3,Follow the standard rules when making connections between the protection board and the lithium-ion battery.Operator should not run any wire across the back of the protection board. Keep them along the side of the board instead.

4,When setting up the protection board, be sure to use a hard epoxy board as an interlayer, to prevent short-circuit caused by the components on the back of the protection board.

5,Both resistive load and inductive load can be used to test battery packs that use this PCB, but not electronic load. Testing with an electronic load will lead to the breakdown of the MOS components on the protection board.

6,Select proper wire gauge to prevent temperature increase from high discharge current (when wire gauge is too high) and excessive voltage drop (when wire gauge is too low).

7,When the PCB is to be installed inside the battery's housing, the user must fully take heat/electric insulation and tightness into account to prevent internal short circuit.

8,Keep any fully charged battery away from children.

9,If any abnormality is detected during use, please stop using the product immediately and notify professional technician to conduct inspection and maintenance.

Product Categories : PCM / BMS > Others PCM / BMS

Other Products

Hot Products

3.7V Battery Chargers for 18650 Rechargeable Battery3.6V lithium ion button cell rechargeable battery lir30481.2v 10000mah Nimh Rechargeable Batteryenergy ER14505 battery AA Size Li-SOCl2 Lithium Battery2018 PKCELL 1.6v 2500mwh rechargeable battery ni-zn high drain batteryPKCELLL brand 6v 7ah lead acid battery SLA for UPS2018 PKCELL 6v 7ah Sealed lead acid rechargeable battery AGM typePKCELL brand 18650 3.7V lithium-ion batteries 2600mah E- cigarette battery

LR03 alkaline battery AAA 1.5v batteries8126 Standard external for 1.2V Ni-MH and Ni-CD battery OEM availablePK1270 12V 7.0Ah Sealed Acid-Lead Battery UPS Battery for Wholesale

PK1270 12V 7.0Ah Sealed Acid-Lead Battery UPS Battery for WholesalePKCELL Brand Blister Package 3.7V 18650 Lithium Battery for Manufacture

LR03 alkaline battery AAA 1.5v batteriesNI ZN AAA 1.6V 900mwh Rechargeable Batteries For Digital Radio3.0 Volt LithiumManganese Battery coin cell CR2330PK12180 Sealed Lead-acid battery 12V 18Ah1300mah nicd sc 1.2v battery rechargeable nicd battery sc 1700mah

1300mah nicd sc 1.2v battery rechargeable nicd battery sc 1700mah9.6v AAA 800mah Nimh Rechargeable Battery Pack with cable